The Benefits of Chesterton Mechanical Seals: Engineering Excellence for Industrial Applications

Mechanical seals are critical components in industrial rotating equipment, and Chesterton has established itself as a global leader in providing high-performance sealing solutions that deliver measurable benefits across diverse applications.

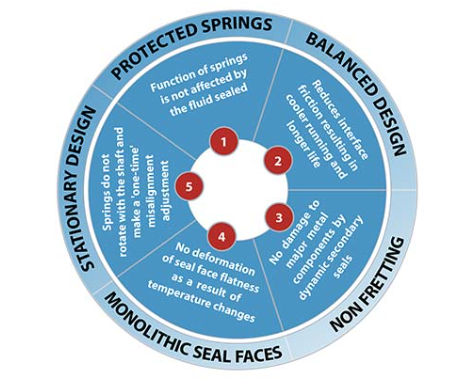

Superior Design Engineering Utilizing the Five Key Features

- Protected Springs - Springs are positioned on the atmospheric side away from process fluids to prevent dirt accumulation and maintain reliable spring function.

- Balanced Design - Reduced hydraulic pressure area on seal faces creates better lubrication, lower heat generation, and decreased wear.

- Monolithic Seal Faces - Single-material seal faces eliminate thermal expansion mismatches and deformation issues that occur with inserted face designs.

- Non-Fretting Design - Dynamic secondary seals positioned on non-metallic surfaces to prevent groove formation and premature failure from repetitive movement.

- Stationary Design - Springs remain fixed rather than rotating with the shaft, eliminating the need for constant adjustment and enabling reliable operation at all speed ranges.

Enhanced Reliability and Performance

Chesterton cartridge seals consistently deliver outstanding reliability and longevity, even when subjected to high-pressure, high-temperature, and corrosive conditions. This exceptional performance stems from their commitment to advanced materials science and precision manufacturing, while innovative face designs optimize fluid film characteristics for maximum operational reliability.

Minimizing Downtime Through Smart Design

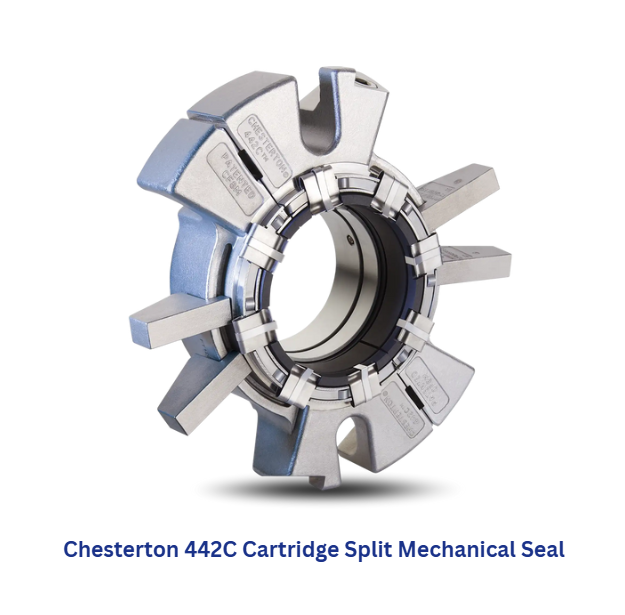

Installation efficiency represents another major advantage of Chesterton mechanical seals. Their cartridge seals incorporate patented innovations such as self-centering retaining rings and adjustable gland lugs, which dramatically simplify installation while reducing costly errors. For challenging applications, the Chesterton 442 & 442C split mechanical seals enable complete seal replacement without removing the pump from service, saving valuable labor hours and eliminating production interruptions.

The mechanical seals also feature patented self-adjusting technology that ensures optimal seal face contact throughout the entire operational lifecycle, maintaining peak performance even under demanding conditions such as pressure-vacuum cycling and high-temperature fluctuations.

Versatile Applications and Cost Benefits

Chesterton mechanical seals excel across diverse industrial environments, from petrochemical and chemical processing facilities to pulp and paper operations, water treatment plants, and power generation facilities. Their versatility makes them suitable for handling everything from aggressive process media to abrasive slurries and corrosive chemicals.

The superior engineering translates directly into tangible cost savings through extended seal life, reduced maintenance requirements, minimized unplanned downtime, reduced water usage and improved energy efficiency. Their superior sealing performance also helps facilities maintain environmental compliance by minimizing fugitive emissions.

Chesterton's proven mechanical seal technologies represent engineered solutions that enhance equipment performance while reducing total ownership costs. Through their combination of advanced materials, innovative design features, and modular flexibility, Chesterton mechanical seals provide the engineering excellence that modern industrial operations require for long-term operational success. Call or email one of our engineers today to learn more about our Chesterton product offerings. Phone: 1-802-255-4003 Email: sales@pumpworld.com